Density of Anti-Crack Mortar

Anti-crack mortar is widely used in external wall insulation systems for bonding and plastering polystyrene boards or extruded boards, effectively preventing wall cracking. It is formulated by mixing cement, sand, anti-cracking agents, and other additives in specific proportions, then blending with water to form a workable mortar. This material helps maintain wall integrity and prevent cracking. The mixing ratio can be adjusted based on actual construction requirements, and its density directly impacts the building’s thermal insulation performance and the service life of the entire external wall insulation system.

As a new type of construction material, anti-crack mortar offers excellent tensile strength, easy construction, and frost resistance. Although it accounts for only a small proportion of the entire external wall insulation system (EC system), it plays a crucial role in connecting insulation materials to the wall, ensuring structural stability.

Construction Method

1.Surface Preparation: Clean the wall surface thoroughly before construction.

2.Mixing Ratio: Mix mortar powder with water at a ratio of 1:0.3 (by weight).

3.Mixing: Stir the ingredients thoroughly until a uniform consistency is achieved.

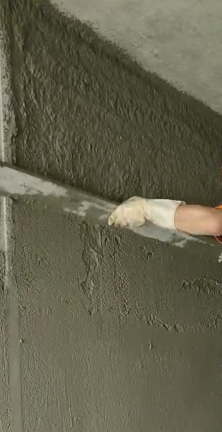

4.Application: Apply the mortar evenly to the wall and smooth the surface.

5.Reference Consumption: Approximately 3-5 kg per square meter (note: original "per cubic meter" is corrected to industry-standard "per square meter" for rationality).

Density Specifications

Wet Density: Approximately 1,600 kg per cubic meter.

Bulk Density (Dry): Approximately 1,250-1,400 kg per cubic meter.

Key Construction Notes

1.Water Ratio Control: Strictly adhere to the recommended water ratio. Excessive water will reduce the mortar’s density, leading to poor bonding strength and compromised thermal insulation. Conversely, insufficient water will result in excessively high density, making construction difficult and causing material waste.

2.No Additional Additives: Do not add any extra admixtures during construction.

3.Pot Life: Use the mixed mortar within the specified time to avoid premature curing.

4.Wall Preparation: Spray water on the wall to maintain appropriate humidity before construction, facilitating easier application.

5.Storage & Transportation:

Store the mortar in a cool, dry, and well-ventilated area.

Protect from moisture, rain, and direct sunlight.

6.Quality Check: Discard any mortar that has hardened or deteriorated, especially for large-scale construction projects.

Product Advantages

Anti-crack mortar exhibits excellent corrosion resistance, strong adhesion, wear resistance, non-toxicity, impact resistance, and waterproof performance, making it a reliable choice for construction applications. However, product quality varies significantly with price. We recommend selecting products based on actual project requirements and conducting thorough market research before purchase.

Every homeowner desires a warm and comfortable living space. When constructing your dream home, attention to detail is crucial. If you plan to use anti-crack mortar, we advise gathering sufficient product information to make an informed decision.