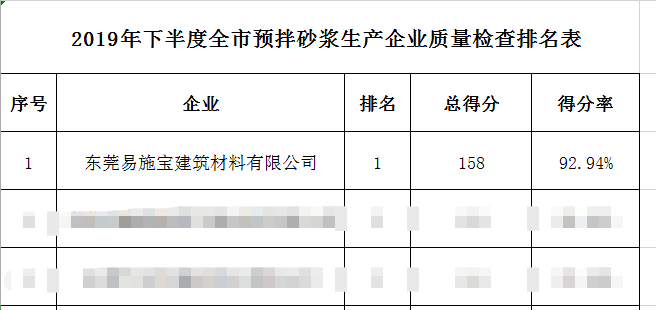

Warm Congratulations to Yishibao for Winning the First Place in the Quality Inspection of Ready-Mixed Mortar Manufacturers in the Second Half of 2019

Warm Congratulations to Yishibao for Achieving 158 Points (92.4% Score Rate) and Securing the First Place in the Quality Inspection of Ready-Mixed Mortar Manufacturers in the Second Half of 2019

To All Ready-Mixed Concrete Manufacturers and Ready-Mixed Mortar Manufacturers:

In order to fully promote the standardized management of ready-mixed concrete and ready-mixed mortar manufacturers in the city and further improve the quality of ready-mixed concrete and ready-mixed mortar in our city, in accordance with the work arrangement of the "Notice on Carrying Out the Quality Inspection of Ready-Mixed Concrete and Ready-Mixed Mortar Manufacturers in the City in the Second Half of 2019" (Dong Jian Zhi Han〔2019〕No. 40), our station conducted inspections on 48 ready-mixed concrete manufacturers and 12 ready-mixed mortar manufacturers in the city from December 2 to December 20, 2019. The inspection results are hereby notified as follows:

I. Overview of the Inspection

The inspection covered 4 key aspects affecting the quality of concrete and mortar, including personnel management, raw material management, laboratory management, and production process control. A quantitative evaluation method was adopted for the inspection.

From the inspection results:

Most ready-mixed concrete manufacturers have relatively standardized management, with traceable factory quality, which is generally under control.

Most ready-mixed mortar manufacturers have an inadequate understanding of the requirements of the competent authorities, incomplete internal management, and an urgent need to improve their management level.

There are 51 supervised ready-mixed mortar manufacturers in the city. Since 39 of them are affiliated to ready-mixed concrete manufacturers, the inspection of ready-mixed mortar manufacturers only targeted 12 independently operated enterprises.

Commendations & Criticisms

Top 6 Ready-Mixed Concrete Manufacturers (Commended):Dongguan Zhongtai Concrete Co., Ltd., Dongguan Junyu Concrete Co., Ltd., Dongguan Jiancheng Concrete Co., Ltd., Dongguan Jiaogang Building Materials Co., Ltd., Dongguan Junye Concrete Co., Ltd., Dongguan Gangchuang Environmental Protection Technology Co., Ltd.

Bottom 5 Ready-Mixed Concrete Manufacturers (Criticized):Dongguan Huashun Concrete Co., Ltd., Dongguan Huasheng Concrete Co., Ltd., Dongguan New World Development Concrete Co., Ltd., Dongguan Guangtai Concrete Co., Ltd., Dongguan Liheng Concrete Co., Ltd.

Ranking of Ready-Mixed Mortar Manufacturers (in order):

1.Dongguan Yishibao Building Materials Co., Ltd.

2.Dongguan Xinyan Building Energy-Saving Materials Co., Ltd.

3.Dongguan Xinghe Building Materials Co., Ltd.

4.Guangdong Jinneng Building Energy-Saving Materials Technology Co., Ltd.

5.Dongguan Henghe Energy-Saving Technology Co., Ltd.

6.Hongma Branch of Dongguan Weiye Cement Co., Ltd.

7.Shijing Lizhan (Dongguan) New Materials Co., Ltd.

8.Dongguan Qingshuang Energy-Saving Materials Co., Ltd.

9.Dongguan Yizhi Mortar Industry Co., Ltd.

10.Dongguan Dongrun Building Materials Co., Ltd.

11.Dongguan Branch of Fujian Rishenghua Technology Co., Ltd.

12.Dongguan Oulia Environmental Protection Materials Co., Ltd.

II. Main Existing Problems

(I) Main Problems of Ready-Mixed Concrete Manufacturers

1.Non-compliance in Raw Material Procurement and Use:

5 enterprises (e.g., Dongguan Huarun Fengcheng Concrete Co., Ltd., Dongguan Junye Concrete Co., Ltd.) had inconsistencies between raw material procurement accounts and online declarations.

7 enterprises (e.g., Dongguan New World Development Concrete Co., Ltd., Dongguan Liheng Concrete Co., Ltd.) had irregularly filled use accounts.

15 enterprises (e.g., Dongguan Xinjian Concrete Co., Ltd.) failed to register private residential information as required.

4 enterprises (e.g., Dongguan Jiansheng Concrete Co., Ltd.) had excessively large batches of incoming materials.

2.Non-compliant Inspection of Concrete Compressive Test Pieces:Dongguan Yushen Concrete Co., Ltd. and Dongguan Huijiang Concrete Co., Ltd. had inconsistencies between production grades and inspection application grades.

3.Inadequate Management of Test Instruments and Equipment:

6 enterprises (e.g., Dongguan Hongji Weiye Concrete Co., Ltd.) had irregular records of concrete impermeability tester usage, and some enterprises lacked sufficient impermeability testers.

3 enterprises (e.g., Dongguan Hongxin Concrete Co., Ltd.) had irregular records of equipment such as concrete penetration resistance testers.

Dongguan Changxing Concrete Co., Ltd. failed to include dust detectors in the verification plan as required.

4.Non-compliant Laboratory Environment Management:

12 enterprises (e.g., Dongguan Huarun Concrete Co., Ltd.) had unsatisfactory operating environments for specific surface area analyzers.

3 enterprises (e.g., Dongguan Shengyuan Ready-Mixed Concrete Co., Ltd.) did not place concrete penetration testers at the corresponding test sites.

Dongguan Yongsheng Concrete Co., Ltd. did not place air content testers at the corresponding test sites.

3 enterprises (e.g., Dongguan New World Development Port Concrete Co., Ltd.) had irregular temperature control in curing rooms.

Dongguan Zhenhuitong Industrial Group Co., Ltd. had irregular curing records for cement curing pools.

6 enterprises (e.g., Dongguan Xietong Concrete Co., Ltd.) had incorrect placement of cement flow tables.

5.Non-compliance with Technical Standards and Management Regulations in Testing:

10 enterprises (e.g., Dongguan Jianye Concrete Co., Ltd.) had irregular rounding of cement specific surface area data.

4 enterprises (e.g., Dongguan Hongxin Concrete Co., Ltd.) had irregular sand and stone test records.

3 enterprises (e.g., Dongguan Hengfeng Concrete Co., Ltd.) had incorrect conclusions in sand and stone test reports.

7 enterprises (e.g., Dongguan Tianren Concrete Co., Ltd.) had incorrect conclusions in admixture test reports.

15 enterprises (e.g., Dongguan Guangtai Concrete Co., Ltd.) had unqualified drawings of admixture setting time difference curves.

9 enterprises (e.g., Dongguan Guangchuang Concrete Co., Ltd.) had incomplete report number registration in original records.

10 enterprises (e.g., Dongguan Fuhuiduo Concrete Co., Ltd.) had incomplete report number registration in mix proportion test reports.

6.Outlier Comparative Test Data:

11 enterprises (e.g., Dongguan Jianye Concrete Co., Ltd.) had outlier data in cement comparative tests.

5 enterprises (e.g., Dongguan Dongtian Concrete Co., Ltd.) had outlier data in sand chloride ion content comparative tests.

Dongguan Chuangji Concrete Co., Ltd. had outlier data in admixture comparative tests.

7.Non-compliant Production Records:

12 enterprises (e.g., Dongguan Guanfeng Concrete Co., Ltd.) generally had incomplete self-inspection records of metering systems or lacked responsible person signatures.

6 enterprises (e.g., Dongguan Shanglong Concrete Co., Ltd.) had inconsistencies between slump values in feeding orders and theoretical mix proportions.

8.Unverified Production Equipment:

Dongguan Guansheng Concrete Co., Ltd. failed to verify the glass thermometer of the negative pressure sieve as required.

Dongguan Huashun Concrete Co., Ltd. failed to verify cement compression fixtures on time.

9.Non-compliant Factory Inspection of Concrete:

4 enterprises (e.g., Dongguan Yifa Concrete Co., Ltd.) had non-standard expression of concrete slump data.

3 enterprises (e.g., Dongguan Guansheng Concrete Co., Ltd.) had incomplete project information.

10.Environmental Pollution Control Issues:

Dongguan Huashun Concrete Co., Ltd. had sprinkler equipment that failed to effectively cover the factory premises.

6 enterprises (e.g., Dongguan Huarun Fengcheng Concrete Co., Ltd.) failed to wash mixing trucks before leaving the factory.

18 enterprises (e.g., Dongguan Xiangsheng Concrete Co., Ltd.) had incomplete or irregularly modified records of solid waste and wastewater treatment.

(II) Main Problems of Ready-Mixed Mortar Manufacturers

1.Inadequate Management of Technical Personnel:

Dongguan Dongrun Building Materials Co., Ltd. had 3 unassigned personnel.

Dongguan Branch of Fujian Rishenghua Technology Co., Ltd. had 3 absent personnel.

Dongguan Yizhi Mortar Industry Co., Ltd. failed to update personnel information on the platform in a timely manner.

2.Chaotic Raw Material Management Accounts:

Dongguan Branch of Fujian Rishenghua Technology Co., Ltd. had incomplete raw material procurement, use accounts, and self-inspection records.

Dongguan Qingshuang Energy-Saving Materials Co., Ltd., Dongguan Oulia Environmental Protection Materials Co., Ltd., Dongguan Dongrun Building Materials Co., Ltd. lacked raw material use accounts.

Most enterprises had non-standard raw material self-inspection practices.

3.Chaotic Management of Test Equipment:

Some enterprises (e.g., Dongguan Oulia Environmental Protection Materials Co., Ltd., Dongguan Branch of Fujian Rishenghua Technology Co., Ltd.) had incomplete identification information for instruments and equipment.

Dongguan Oulia Environmental Protection Materials Co., Ltd. lacked a cement paste mixer.

Dongguan Branch of Fujian Rishenghua Technology Co., Ltd. lacked a cement mortar mixer.

Many enterprises (e.g., Dongguan Oulia Environmental Protection Materials Co., Ltd., Dongguan Yizhi Mortar Industry Co., Ltd.) had no verification plans for instruments and equipment.

Most enterprises had incomplete or missing instrument usage records.

4.Laboratory Environment Issues:

Except for Dongguan Oulia Environmental Protection Materials Co., Ltd., Dongguan Branch of Fujian Rishenghua Technology Co., Ltd., Dongguan Yizhi Mortar Industry Co., Ltd., Dongguan Yishibao Building Materials Co., Ltd., and Guangdong Jinneng Building Energy-Saving Materials Technology Co., Ltd., other enterprises had irregular placement of test instruments and unsatisfactory operating environments.

Except for Dongguan Xinyan Building Energy-Saving Materials Co., Ltd., Dongguan Yishibao Building Materials Co., Ltd., and Dongguan Xinghe Building Materials Co., Ltd., other enterprises had irregular temperature control in curing rooms.

5.Non-compliant Testing and Sampling:

Dongguan Henghe Energy-Saving Technology Co., Ltd. had irregular sand chloride ion test reports.

Guangdong Jinneng Building Energy-Saving Materials Technology Co., Ltd. failed to test cement by batch as required.

Dongguan Branch of Fujian Rishenghua Technology Co., Ltd. had insufficient cement inspection batches.

Dongguan Oulia Environmental Protection Materials Co., Ltd. and Dongguan Yizhi Mortar Industry Co., Ltd. had no original test records.

Except for Dongguan Yishibao Building Materials Co., Ltd. and Dongguan Henghe Energy-Saving Technology Co., Ltd., other enterprises had irregular modifications to original test records.

Except for Dongguan Henghe Energy-Saving Technology Co., Ltd., Dongguan Xinyan Building Energy-Saving Materials Co., Ltd., and Dongguan Qingshuang Energy-Saving Materials Co., Ltd., other enterprises had inadequate sampling quantity and time limits.

6.Unverified Production Equipment and Uncontrolled Product Quality:

Dongguan Oulia Environmental Protection Materials Co., Ltd. failed to verify production equipment as required.

Many enterprises (e.g., Dongguan Yizhi Mortar Industry Co., Ltd., Dongguan Dongrun Building Materials Co., Ltd.) failed to sample or had irregular sampling records.

Dongguan Henghe Energy-Saving Technology Co., Ltd. and Dongguan Xinyan Building Energy-Saving Materials Co., Ltd. had irregular filling of factory quality certificates.

Most enterprises had incomplete or irregular records of mortar performance inspection information.