Flexible Waterproofing Membrane FWP88 -ll

-

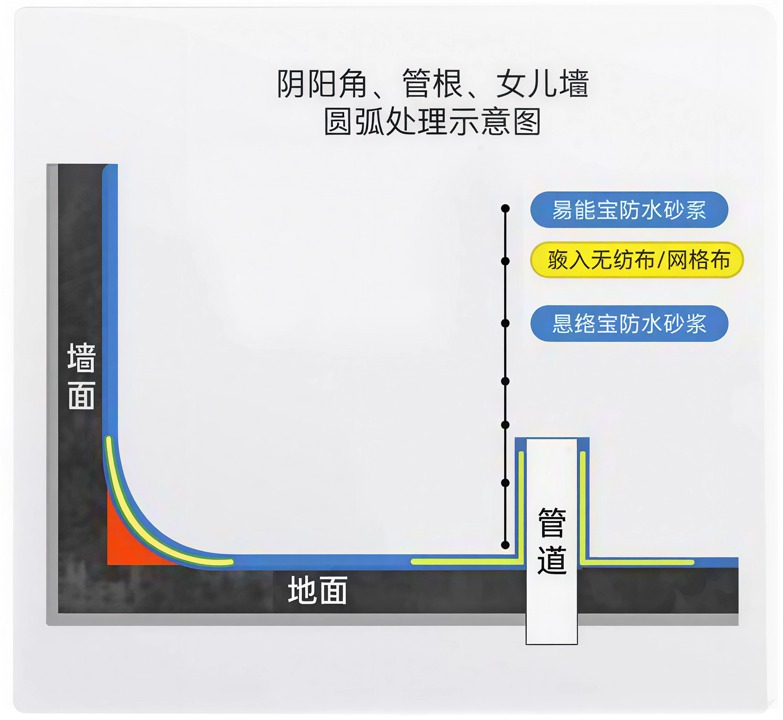

Detail

Flexible Waterproofing MembraneFWP88-II

Product Description

EasyMix Flexible Waterproofing Membrane FWP88-II consists of two parts: part A(powder) and part B(liquid)is a two-component waterproofing and protective system.It is a flexible cementitious coating which is based on elasticity of acrylic copolymer reinforced by selected aggregates and fillers. It is applied as slurry and dries to form a membrane to vapour but works as a barrier to water and moisture.

Product usage

Suitable for waterproofing of concrete structures, brick and masonry works. Roof, Planter box, Environmental deck, Basement wall, Bathroom and toilet, Balcony, Kitchen,Water tank, Lift pit,Swimming pool.

Advantages

1.Very suitable for concrete and cementitious substrate surface. Easy to apply,can be applyon wet substrate.

2.Polymer modification, excellent bonding on concrete and masonry surfaces.

3.Flexible and breathable but provide complete protection against moisture penetration.

4.It fills and bridges hairline cracks and stays fully bonded

5.Environmental protection, non-toxic and harmless. Reduces the risk of moss, fungusgrowth and efflorescence.

6.Good durability and weather resistance, lasting protection.Specification & Technical data: GB/T 23445 / EN14891

Testing itemsTechnical data Solid content (%)≥70 Tensile strength

Initial breaking strength(MPa) ≥1.8 Retention rate after heaing aging(%) ≥80 Retention rate after alkali treatment(%) ≥70 Retention rate after waterwater immersion(%) ≥70 Retention rate after UVtreatment(%) --- Elongationat break Initial breaking strength(MPa) ≥80 Retention rate after heaing(%) ≥65 Retention rate after alkalis treatment(%) ≥65 Retention rate after waterimmersion(%) ≥65 Retention rate after UVtreatment(%) --- low temperature softness characteristic, p10mm rod --- Bong streng(N/nm2) Initial(MPa) ≥0.7 At wet substrate (MPa) ≥0.7 After alkalis treatment(%) ≥0.7 After water immersion(%) ≥0.7 Water Impermeabilty (0.3MPa,30min) Impermeable lmpermeabilty(-ve pressure)(MPa) ≥0.6 Application

一,Substrate Surface Preparation

1.Remove all deteriorated concrete, dirt, oil, grease and other bond inhibiting materials from thesurface cleaning should be done by sandblasting, high pressure water blasting, grinding or other appropriate mechanical means.

2.Repair recessed area and holes with EasyPlas repair mortar and remove any protruded area. UseEasyPlas Primer EPP308 to treat high water absorption substrate.

3.Newly cast concrete should be fully cured and old concrete should be thoroughly cleaned before application,

4.For old concrete substrate, wash the substrate and prime the substrate with primer EPP308 before application.二,Application

1.Mixing Procedure

1.Mix Part A powder to Part B liquid in a clean container with a low speed mechanical mixer.Carefullymix 3-5min to disperse the powder until a slurry consistency is achieved.

2.Avoid excessive or high speed mixing which may entrap air into the mix.

3.Mix ratio( Part A : Part B) FWP88-II is 1.8 : 1, not allow to change the ratio.二.The correct construction technology makequality waterproof effect.

1.There are lots of capillary channels in concrete andmortar, any flaw of waterproof membran can lead towater seepage.

2.Focus the leak point is very important.

二.Application:Key point1.Clean the substrate,apply the first coat with a stiff brush to cover the corner and the root of thewater pipe, Embed the suitable weight and size non-woven fabrics/glass fiber mesh in waterproofmembrane. Apply second coat with a stiff brush to cover the non-woven fabrics/glass fiber mesh.

2.Non-woven fabric/glass fiber mesh should be laid without folds, smooth and practical,overlapping position should pay attention to the lap ≥10 cm width.Large area paint treatment

1.Apply the first coat with a stiff brush to cover the substrate completely, especially at edgesand corners.

2.The second coat may be applied with a soft brush or roller when the first has become tack free after3 to 5 hours(depending on the ambient condition)

3.The second coat should apply at the right angle perpendicular to the first coat to avoidpinholes and un-brushed areas.

4.The recommended thickness is 1~2mm depending on the expected water pressure and abrasion.

5.No walk allowed within 24 hours after application. Protective topping shall be installed to furtherenh ance the durability of FWP88-II. -

Customer ReviewsNo comments