Home

/

Self-Leveling Compound Over-layment SLO-924

Self-Leveling Compound Over-layment SLO-924

Customize your products in every detail, we provide customized service for you. If you have any requirements on the shape, dimensions, function, or other aspects of your products, or if you have any new creative products to be developed, you can contact our team and we will work out the most cost-effective production plan for you.

Quantity

-

DetailSelf-Leveling Overlayment ScreedSLO-924

Product Description

EasyMix Self-Leveling Overlayment Screed is ahigh-performance floor overlay material developed withadvanced German technology. It offers excellent flowability,low shrinkage, strongadhesion, as well as high adhesion tocompression and abrasion.

Uses

This multi-purpose self-leveling overlay provides both substrate leveling and decorative surfacing, engineered for commercial spaces like offices, retail centers, and parking facilities.

Advantages

1.Easy to use,quick and convenient operation, fast curing time,time-saving.2.High fluidity enables seamless self-leveling, resulting in a flat surface and visually appealing finish

3.Once hardened, the material remains crack-resistant and free from delamination or debonding.

4.High strength, Abrasion resistance.

5.Uniform , Color is optional

Specification & Technical data : JC/T 985-2017

Product CharacteristicsSelf-Leveling Overlayment ScreedInitial flow rate≥130Tensile adhesion strength≥1.0Dimensional change rate-0.1~+0.1Flexural strength(24 day)≥2.0Compressive strength(24 day)≥6.0Flexural strength(28 day)≥7.0Compressive strength(28 day)≥30.0

Application

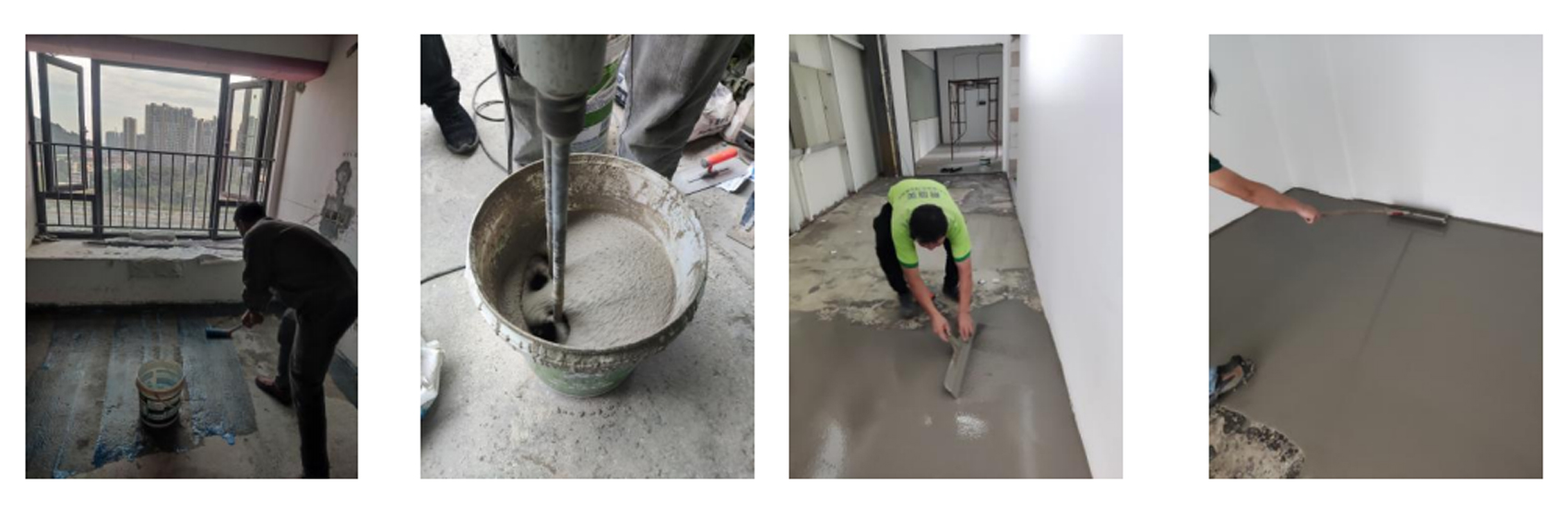

1,Substrate Surface Preparation

1.Existing cracks are sectioned, cleaned, and repaired. On fresh concrete surfaces that haveachieved design strength and full curing, mechanical grinding is applied to eliminate laitance or compromised surface material.

2.Contaminated substrates (grease, cured coatings, etc.) compromising adhesion shall undergoabrasive blasting or scarification. Post-mechanical treatment, achieve cleanliness via vacuuming.

3.After cleaning the floor with a vacuum cleaner, apply a concrete interface bonding agentfor surface treatment.

4.Place expansion joint foam strips along the perimeter walls before pouring self-levelingflooring to prevent stress cracks from wall contact.

5.For significant substrate cracks or over-thick applications, contact our technical team to ensurea proper resolution.

2,Application

1.Use an electronic scale to measure the mixing water. Unauthorized increases in water contentmay lead to issues such as bleeding, delamination, color variation, or cracking.

2.Employ an adjustable-speed dual-paddle mixer. First, mix at high speed for 2-3 minutes toachieve thorough homogeneity. Allow the mixture to rest (mature) for 2 minutes, then stir at lowspeed for 1 minute before pouring onto the floor.

3.Spread the material uniformly in horizontal strips across the substrate. Use a notched trowel torapidly level the mixture. Assist the process with an infrared level and an aluminum straightedgeto ensure flatness. Immediately after spreading, roll the surface with a deaeration roller toeliminate air bubbles, construction seams, and trowel marks.

4.Barricade the work area and close all doors/windows to allow the floor to dry and cure naturally

5.Two days after self-leveling compound application, cut the material along the original floorexpansion joints using a grooving tool. This prevents random cracking at the joints caused bysubstrate shrinkage.

Notes

1.The application temperature is 5~35℃,and you should familiarize yourself with the overall applicationprocess before application. Note that in direct sunlight, strong wind blowing and other circumstancesmay appear grout surface drying too quickly.

2.In order to achieve the best application effect, the substrate layer should be clean, oil-free, dust-free, freeof pollutants or isolation materials.

3.It can be applied in a thickness over 5-10mm.

4.Install isolation buffer sponge strips around perimeter walls during construction to minimize stresscracking caused by contact between the self-leveling compound and the walls.

5.Cut and fill shrinkage joints in the substrate concrete promptly with flexible sealant to accommodatematerial contraction.

6.The original sealed product is stored in a dry, cool and ventilated environment and has a shelf life of 9months under normal storage and transportation conditions. Do not freeze. -

Customer ReviewsNo comments