Slurry Water-proofing SWP188

-

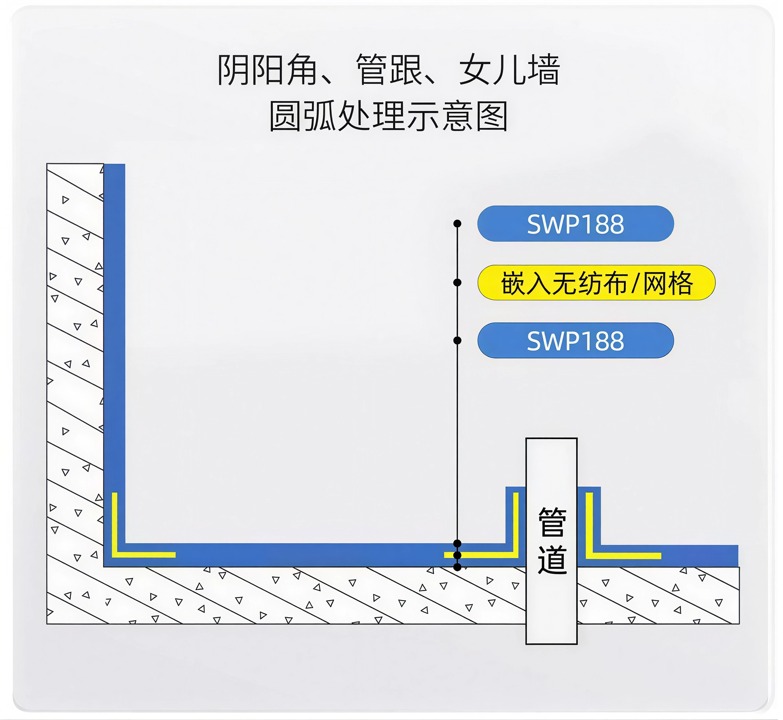

Detail

Slurry Water-proofing SWP188

Product Description

SWP188 waterproof coating is formulated with cement, selected aggregates and polymer additives in proper proportion. It is a new flexible waterproof material with certain permeability, consisting of dry material (Part A) and liquid additive (Part B). When mixed, it serves as a waterproof material that delivers excellent workability and outstanding adhesion to various base materials.

Application

1.Waterproof coating for indoor/outdoor cement concrete structures, cement mortar, brick walls and other bases

2.applicable to bathrooms, basements, exterior walls, roofs, balconies, drinking water tanks, swimming pools, sewage tanks, reservoir dams, tunnels, bridges, elevated highways and building platforms of new/old buildings.Product Features

1. Easy construction, applicable in damp areas

2. Polymer-modified, enhancing adhesion to various substrates

3. Good flexibility, breathable & impermeable

4. Eco-friendly, non-toxic, wide application range

5. Excellent durability, strong weather resistance, long-lasting protectionExecutive Standard & Technical Parameters JC/T 2090-2011

Test items Type II Specifications Drying Time Surface drying ≤4h Actual drying ≤8h Anti-seepage Pressure(MPa) ≥1.0 Flexibility Lateral deformation ---- Flexibility No cracks cracking/creases moist base ≥0.7 Alkali treatment ≥0.7 Soaking treatment ≥0.7 Alkali resistance No cracking or peeling heat resistance No cracking or peeling Frost resistance No cracking or peeling

1.Universal waterproof mortar construction process and construction methods一. Base Treatment1-1Proper base preparation is critical for waterproofing1.Confirm the base material is firm, flat, and free of hollowing; the base surface is clean, free of oil stains, release agents, dust, loose materials, etc. Use a high-pressure water gun (about 150bar) or other effective methods to remove stubborn stains.

2.Cracks on the base surface should be repaired in advance; it is recommended to use EasyBond repair mortar. Protrusions should be knocked off. For loose and porous base materials, apply EasyBond primer interface agent EPP308.

3.Waterproof mortar can only be applied after the primed base surface cures; clean floating mortar and release agent on the surface thoroughly.

4.For old concrete surfaces, thoroughly clean dirt, apply EPP308, then apply waterproof mortar.

5.For exposed environments (e.g., roof), apply 1-2 coats of EasyBond primer EPP308.

6.Clean the base before construction (no standing water). Pre-apply EasyBond primer EPP308; apply waterproof coating after it dries to reduce air bubbles/holes caused by base moisture, improving waterproofing efficiency.2.Waterproof Coating Construction Process

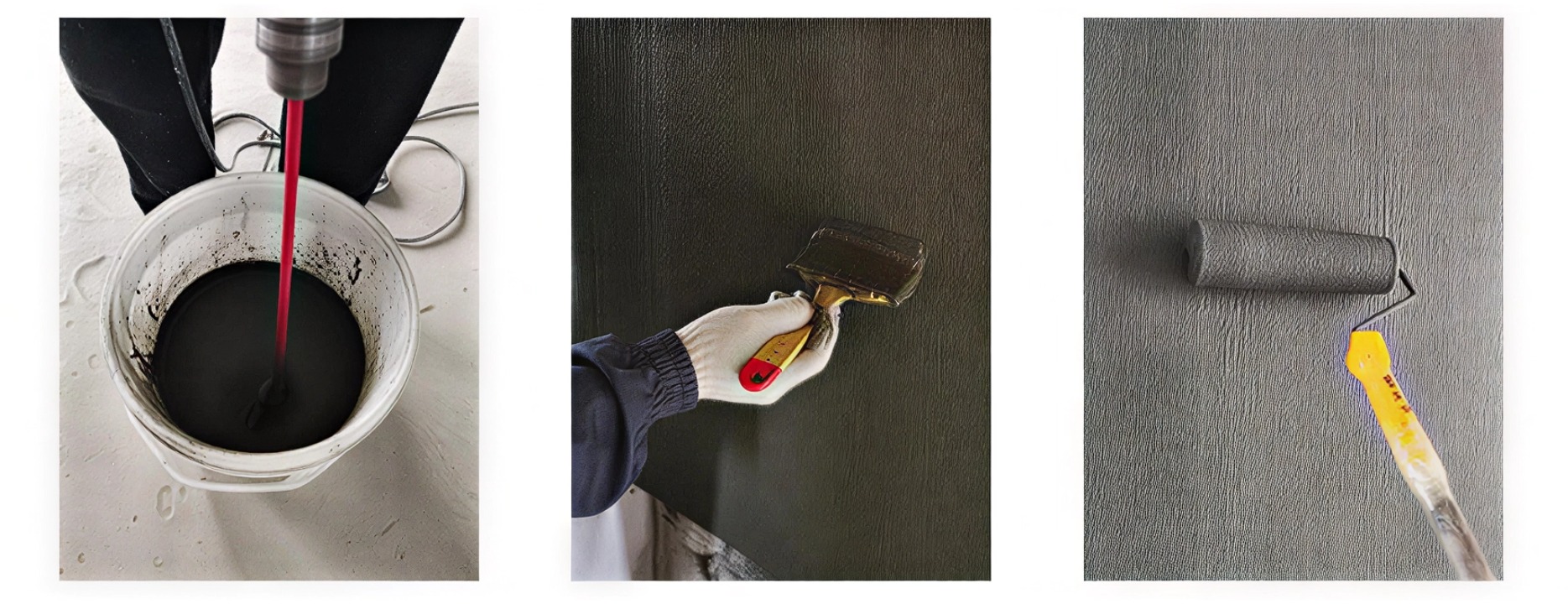

2-1. Waterproof Coating Mixing

1.For optimal results, use mechanical mixing (low-speed <600rpm, high-power electric drill mixer recommended).

2.In a suitable container, pour liquid additive Part B first; keep the mixer running at low speed, slowly add EasyBond powder Part A, and mix until uniform (no lumps).

3.Do NOT arbitrarily change the mixing ratio.4.After mixing into a fluid paste, let it stand for 1-2 minutes, then mix again for 1-2 minutes. (Do NOT add extra water.)2-2. Correct construction process is key to waterproofing effects.

1.Concrete/mortar has many capillary channels; any missed brushing/breakage in the coating may cause water seepage.

2.Proper node treatment is critical to preventing leakage.

2-3. Waterproof Coating Construction:Node Treatment1.After cleaning the internal corner, brush the first coat of waterproof coating on internal corners/pipe roots; embed pre-cut non-woven fabric/fiberglass mesh cloth (appropriate weight) into the coating, press firmly with a trowel/brush, then apply the second coat on the cloth.

2.Lay non-woven fabric/fiberglass mesh cloth smoothly (no wrinkles); overlap width ≥10 cm.2-3-2. Large-Area Brushing Treatment

1.Clean the base thoroughly (control humidity); use EasyBond primer EPP308 to reduce air bubbles/holes from base moisture, improving efficiency.

2.Apply mixed mortar evenly to the base with a brush/sprayer; check for defects/missed areas.

3. Apply at least 2 coats; wait 1-2 hours for the first coat to dry before applying the second (do NOT apply wet-on-wet).

4.Apply the two coats in a crisscross direction to fill missed holes.

5.Do NOT step on the coating within 24 hours; proceed to the next process only after full curing.6.Prevent rapid water evaporation (high temperature/strong wind) by closing doors/windows or covering with plastic film for curing.

Notes1. Construction temperature: 5~35°C. Avoid outdoor construction on rainy days; avoid strong wind/direct sunlight within 24 hours post-construction. Pre-apply EasyBond primer EPP308 for outdoor work.

2. The base layer must be properly treated and kept moderately moist.

3. Do NOT change the mixing ratio (e.g., adjust component proportions, add extra water/cement).

4. Use mixed mortar within 1-2 hours; do NOT re-mix dried mortar with water.

5. This product contains cement (produces alkaline substances when wet); protect skin/eyes.

6. Shelf life: 9-12 months (store sealed product in dry, cool, ventilated conditions). This product contains emulsion—avoid freezing. -

Customer ReviewsNo comments