Water-based Sheen Coating

-

Detail

Water-based Sheen Coating

product Overview

EasyPlas® Water-based Soft Gloss Topcoat is a water-based organic silicon modified pure acrylic polymer with soft glossiness and high water resistance. This product adopts advanced production technology; the polymer particles are extremely small in diameter and evenly distributed, featuring strong permeability and sealing properties.

product Uses

With small particle size, strong permeability, high transparency after drying and soft gloss, this product is very suitable for topcoating of interior and exterior walls, art paint, stone paint, and multi-color paint. It can also be used for topcoating of indoor self-leveling floors and micro-cement, helping to create a warm and comfortable atmosphere.

Features

1.Water-based product, safe and eco-friendly

2.Nano particle size, deeper penetration

3.Seals capillaries, reduces water absorption rate

4.Room-temperature self-crosslinking polymer, fast drying speed

5.Excellent adhesion performance

6.Excellent water resistance and anti-whitening performance

7.Firmer film formation, high gloss, high hardness, wear-resistant, with excellent durability and weather resistanceExecution Standard: JG/T 24-2018 Synthetic Resin Emulsion Sand Wall Architectural Coatings

roduct Characteristics Requirements for Transparent Surface Coating Condition in container No caking after stirring, uniform state Applicability No obstacles during application Drying time (surface dry)/h ≤2 Coating appearance Normal Low-temperature stability (3 cycles) No deterioration Alkali resistance No abnormality after 96h Coating temperature change resistance (5 cycles) No abnormality Stain resistance % ≤15 Water whitening resistance (24h)/△w ≤5.0 1,Base Treatment

1.1. Ensure the facing material is firm, flat, free of hollowing, and clean.

1.2. The base facing material should be completely dry and have appropriate absorbency; if there is dust, remove it with a vacuum cleaner or hair dryer.

1.3. Apply the topcoat to the finished facing material as soon as possible to reduce the impact of rainwater and human contamination.

1.4. This product has very high adhesion after drying; cover and protect parts like doors, windows, lamps, and masonry in advance to prevent contamination.2, Topcoat Construction

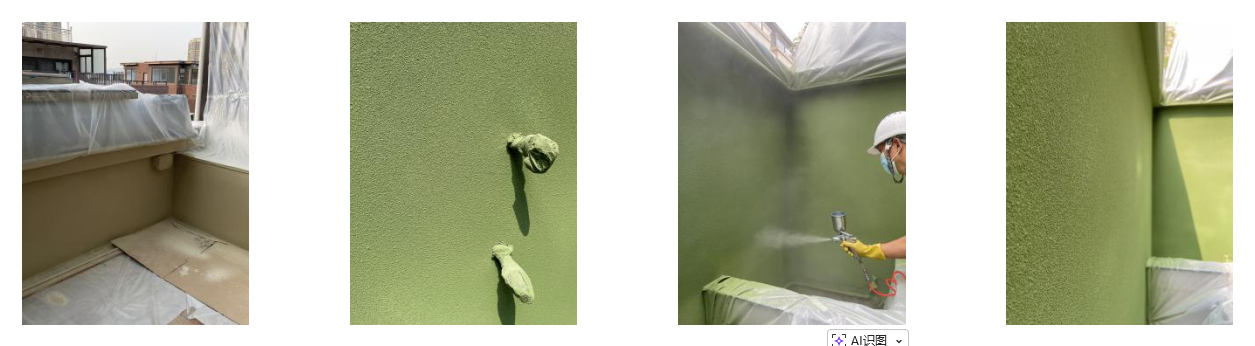

2.1. Apply the topcoat evenly on the facing material using a roller, brush or spray pot, and wait until it is completely dry.

2.2. For better protection, a second rolling can be done after the topcoat dries.

2.3. Roller Application: For the first roll coating, add 10-30% clean water to the topcoat emulsion appropriately to reduce the solid content; roll the second topcoat after it dries. This can reduce differences in color and gloss caused by uneven rolling and inconsistent absorption of the facing mortar.

2.4. Spray Application: During spraying, note that the nozzle distance from the wall should not be less than 50 cm; too close a distance may cause uneven spraying.

precautions1. The base must be clean, dry, free of dust, oil stains, paint, and loose materials.

2. The construction temperature is 5~35℃; familiarize yourself with the overall construction process before construction.

3. This product is a water-based eco-friendly product with no flammable risk.

4. This product forms a firm film, with adhesion and hardness comparable to oil-based resins.

5. This product can reduce the base absorbency, but it cannot be used as a separate waterproof material.

6. This product is a slag-free product, but it is recommended to wear gloves and goggles during use; clean the tools with clean water immediately after use.

7. Shelf Life: Store the original sealed product in a dry, cool, and ventilated environment. Under normal storage and transportation conditions, the shelf life is 12 months; prevent low-temperature freezing. -

Customer ReviewsNo comments